Products & Solutions Coke Oven Machines

Weight saving and environmentally friendly technology

We can provide lifecycle solutions for the design, production, installation, and diagnosis of coke oven machines through technological innovation based on our vast experience and technologies.

Features

- We are keeping over 90% domestic market share.

- Stable operation and improvement of environmental performance by diagnosis for existing machines.

- Modification and repair of existing machines.

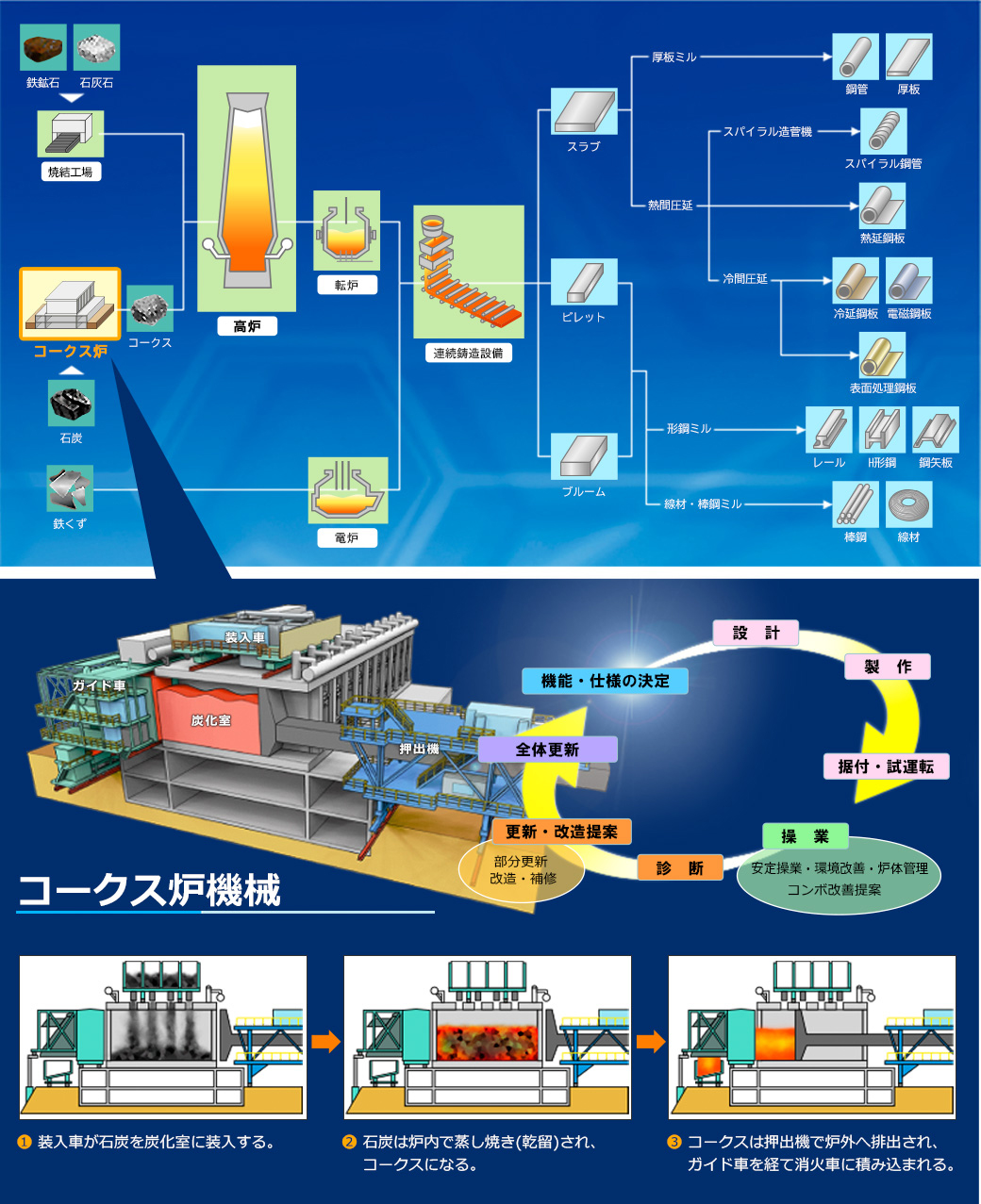

CHECK POINT 01 Mechanism of coke oven

Product Line up

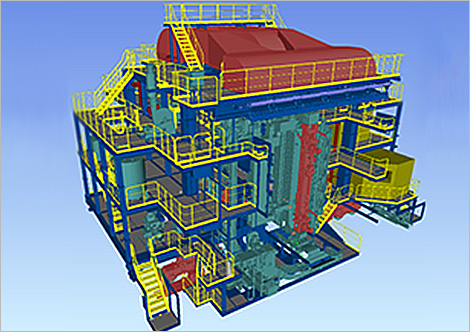

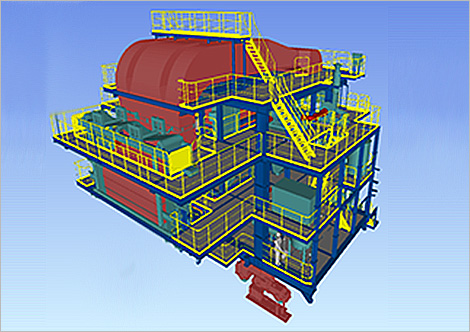

01 Coke Oven Machines

We can provide coke oven machines necessary for iron manufacturing such as pusher car, CTC (Guide Car), charging car, and quenching locomotive.

Charging Car: Charge coal into the carbonization room.

Pusher Car: Push coke from the chambers.

CTC (Guide Car): Guide coke to the quenching locomotive.

CTC (Guide Car)

Guide car offers excellent environmental performance, realizing a substantial gas reduction that is discharged from the coke oven into the atmosphere. We are the unique company in Japan.

- ※1 CTC:Coke Transfer Car

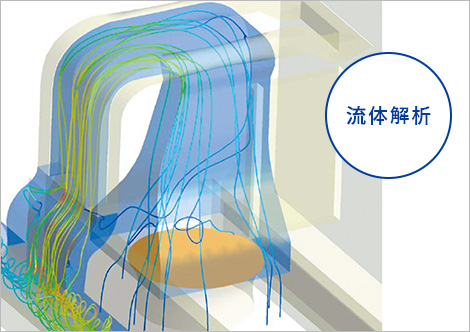

- ※2 Analysis of gas flow between ground duct and connectors by CFD (Computational Fluid Dynamics).

CTC※1(Guide Car)of emission collecting system※2

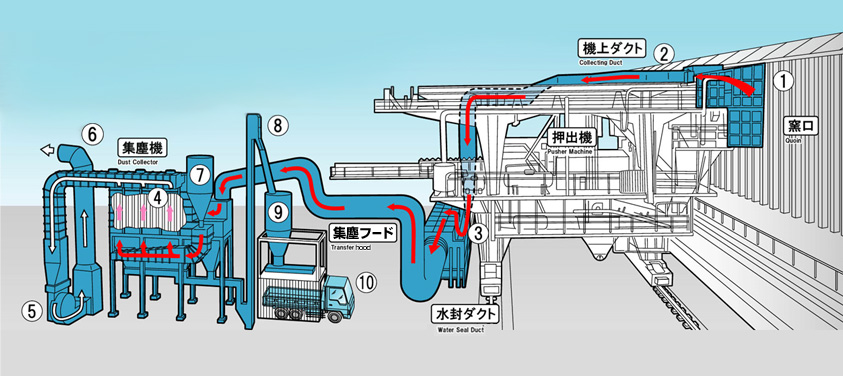

02 Machine side door emission collecting system

This emission collecting system has excellent environmental performance to enhance emission collection efficiency, which is also highly appreciated worldwide.

Sumitomo Heavy Industries Process Equipment Co., Ltd.

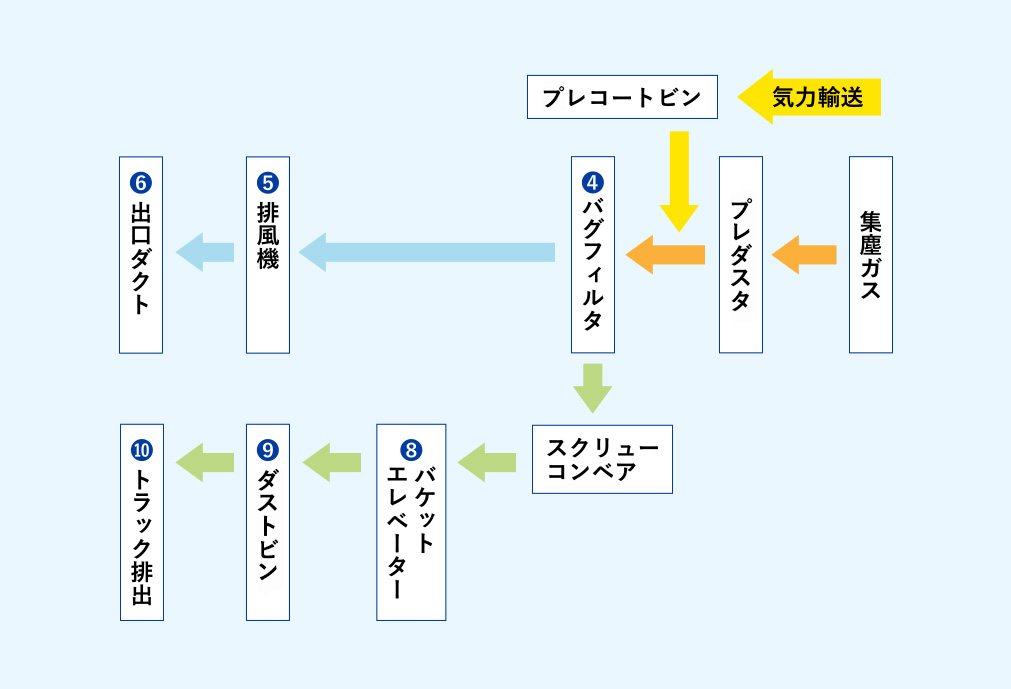

CHECK POINT 01 Dust collector specifications

- Dust collector method

- pulse bug filter (precoated)

- Process air volume

- ~2,000m3/min

- Air volume control

- inverter method

- Filtration area

- 1,420m2

- Precoated provision

- pneumatic transportation

CHECK POINT 02 Features

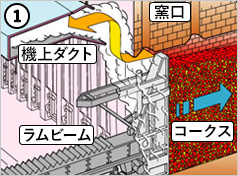

01 Inlet

Dust will be collected in response to dust emission pattern that occurs in a series of kiln discharge processes.

- (1) Optimum inlet port shape set by airflow analysis.

- (2) Dust emission is absorbed as a priority by the lower flap installed on the suction mouth.

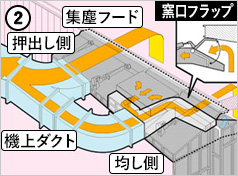

02 Dust collector hood

The compact hood operates with no issues, wrapping up and collecting remaining dust emission.

- (1) Dust emitted during leveling is collected by the leveling opening duct.

- (2) Leakage from between the furnace and hood is prevented by the furnace opening flap.

- (3) When the dust collector stops, the flap is opened and heat within the hood is released.

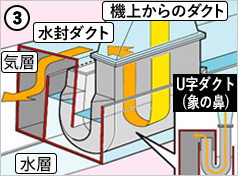

03 Water seal duct

Dust collection capacity will be used to its maximum through use of the U-Duct (elephant nose).

- (1) There is no leakage from the connector.

- (2) Location of dust emission is not chosen.

- (3) Maintenance is made easy by separating the water layer and gaseous layer.

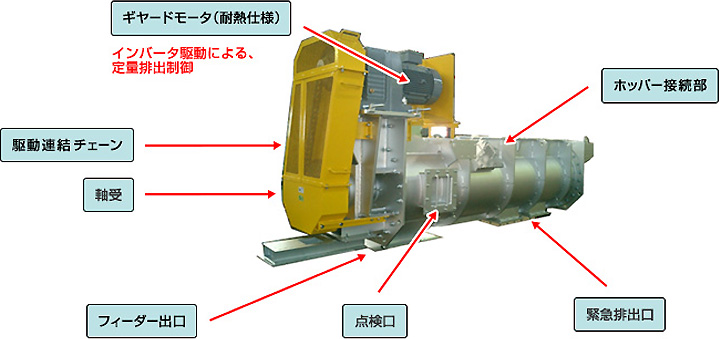

03 Screw Feeder

We can provide a screw feeder for charging car.

This equipment exhibits a stable charge based on high environmental performance using closed type and constant-volume conveyance.

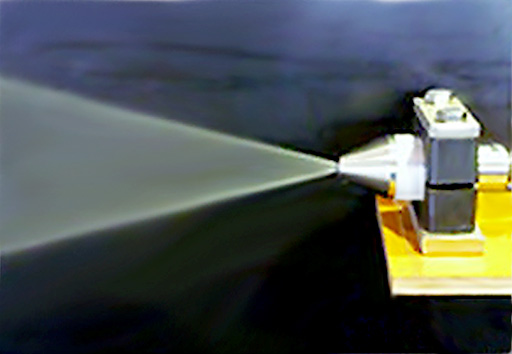

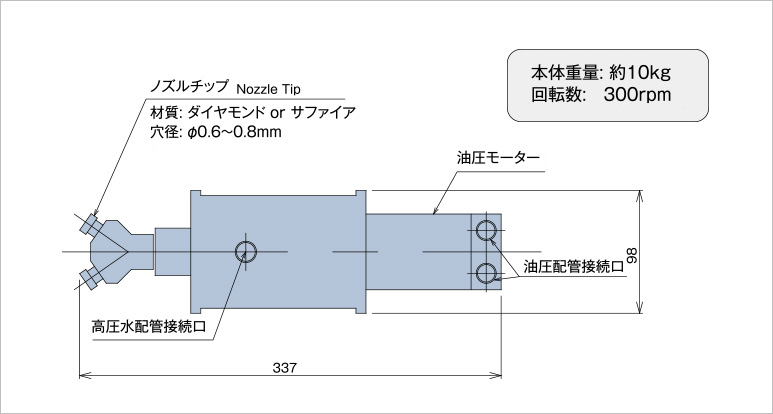

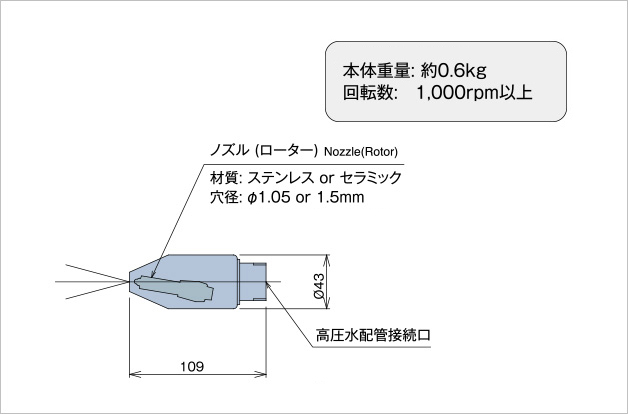

04 Self-Rotating Nozzle Gun

We can provide coke oven door cleaner with self-rotating nozzle gun driven by light-pressure water equipment instead of hydraulic pressure models. It enables to reduce costs, improve maintenance and decrease downtime due to oil pressure failure.

- Before

-

- After

-

General Type

Self Rotating Nozzle Gun

Catalog

The catalog introduces the Self-Rotating Nozzle Gun.

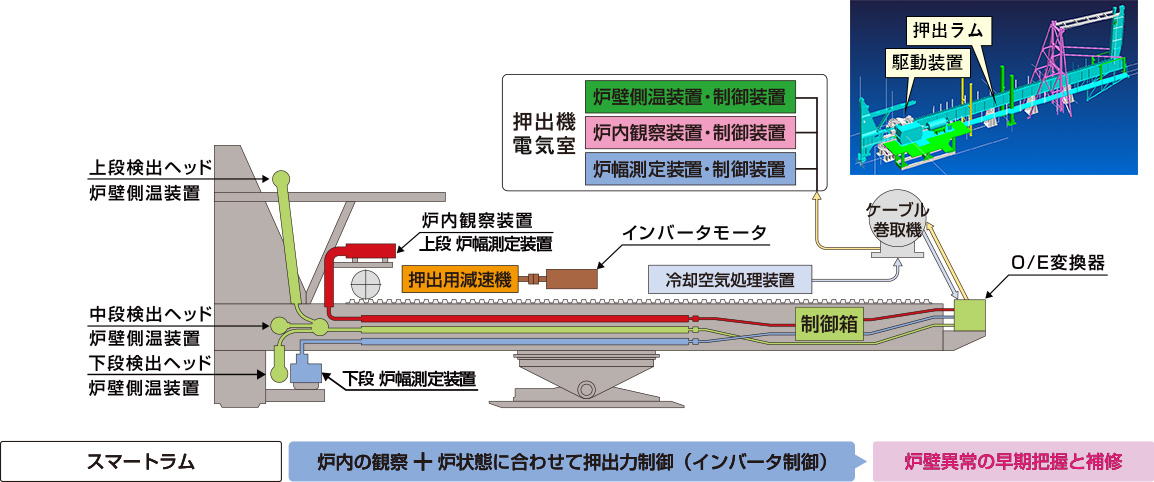

05 Smart Ram

We can provide a ram beam system that equipped with inner observation device, width measuring device and wall temperature measuring device. It enables to observe wall, measure width and wall temperature of chamber while pushing coke.

- Inner observation device

- Used to observe the inside of the high-temperature chamber approximately 1200℃ with image.

- Width measuring device

- Used to measure the dimensions of oven wall roughness that is caused by deterioration.

- Wall temperature measuring device

- Used to measure the temperature of the wall surface of the chamber. This device can also notify coke-combustion management of a feedback and detect oven wall damage due to a temperature error.