Products & Solutions Steel Structures

Large-scale canning and welding products fabricated by world-class facilities

We can provide high-tensile strength steel welding technology that we gained by manufacturing of the Honshu-Shikoku Bridge.

Features

- Marine transportation of large-scale canning products is available.

- Handling Capacity of the Jib crane is 320 tons or less.

- Manufacturing of extra thickness steel structures based on pressure vessels is available.

- OEM supply of construction machines (crawler crane and mining machine)

Lineup

LINE UP 01 Steel structures for harbor facilities

Manufacturing of hybrid caissons, jackets, pontoons, dock gates, dock doorstops, discharge pipes, and river gates.

Hybrid caisson for Yokosuka port

Jacket for break water for Yuge port

Pontoon for Mishima-Kawanoe port

Submerged tunnel for Naha port

Steel frame for nuclear power plant

LINE UP 02 Large-scale steel structures

Manufacturing of GC girders, JC portals, piers, converters and large pots for molten steel.

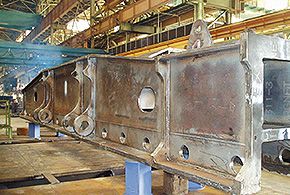

LINE UP 03 Construction machines

Manufacturing of crawler cranes and mining machines.

Boom

Assembly

Mobile crane

Oil field shovel

Swing frame

Side frame

Factory and major facilities

Saijo Factory

- Land Area

- 535,000m2

- Floor Space

- 48,000m2

We manufacture large pressure vessels that are approved by ASME and various regulations. Our technologies allow for the welding of extremely thick materials and other such special materials.

By applying our large scale canning machine and welding technology, which we have developed through bridge engineering, we fabricate large steel structures with reliable manufacturing.