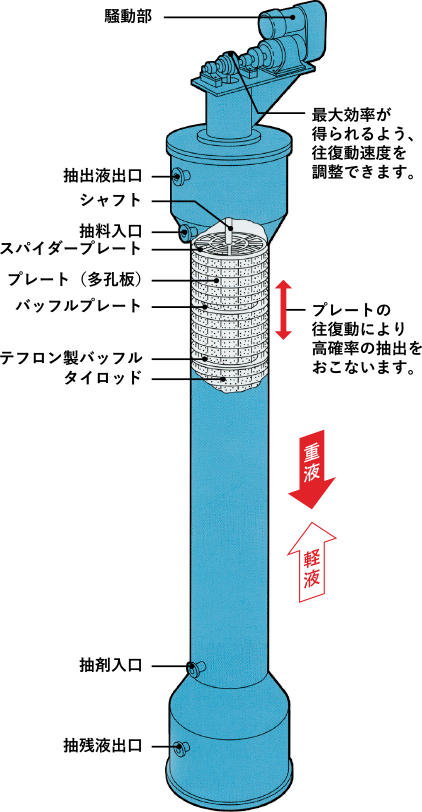

Distillation & Liquid-Liquid Extractor Liquid-Liquid Extractor

Liquid-Liquid Extractor, having high throughput capability and suitable for high theoretical plate process.

Our reciprocating-type liquid-liquid extractor, having high throughput capability and suitable for high theoretical plate process, are applied widely to extraction process in various fields such as the chemical, petrochemical, pharmaceutical and nonferrous metal industry.

Efficient liquid dispersion

The internal part, "plate stack", is mainly comprised of the perforated plate and baffle plate and moves up and down inside column.

Liquid is efficiently dispersed by vertical motions of the perforated plate which opening ratio is approximately 50%.

Reciprocating extraction tower

The figure liquid is heavy liquid,

shows the case extractant is of light liquid.

Features

- The actual scale-up method is established from data of pilot column.

- The maximum throughput per cross section at the counter-current part is approximately 60 (m3/m2hr), depending on the process, and leads column to be compact.

- Efficient liquid-liquid contact is possible in all parts of the column cross section.

- Extractor has been delivered to various fields such as the chemical, petrochemical, pharmaceutical and nonferrous metal industry.