Course 4

Consider a mixing vessel as a huge viscometer

Course 4

Consider a mixing vessel as a huge viscometer

In the previous session, It is explained that ;

(1) There are many fluids so-called “Non-Newtonian fluids”, which greatly change the apparent viscosity depending on the shear rate.

(2) In the mixing of Non-Newtonian fluids, experience and sense are essential for proper handling because the liquid viscosity varies widely in a mixing vessel depending on the shape and rotation speed of the impeller.

Now, in this session, we will explain how to handle such a troublesome viscosity a little more specifically.

Who is deciding viscosity with what definition?

By the way, How does the so-called viscosity is determined?

To get this anewer, let's return to the origin. we explain how and by what measuring instrument viscosity is usually measured.

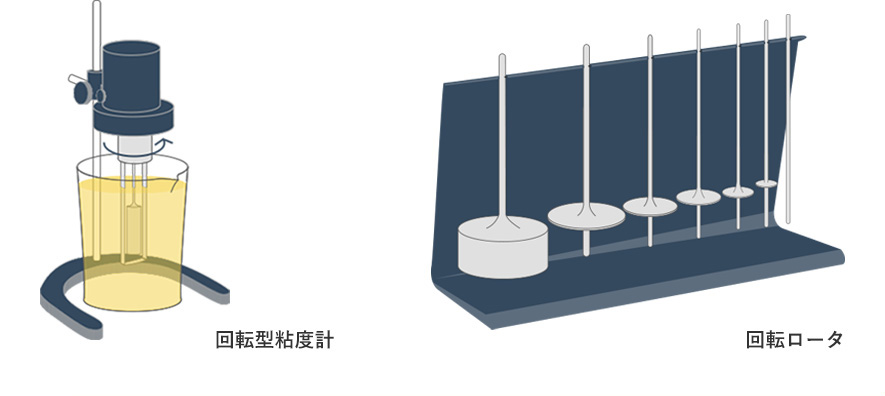

There are various types of viscosity measuring instruments, that is, Viscometers, but usually “Rotational Viscometers” are used. The measurement procedure for viscosity is as follows:

1. Pour the liquid in a beaker, select the rotor appropriate for the stickiness of the liquid, then immerse the rotor in the liquid.

2. Rotate the rotor at a rotation speed appropriate for the measurement range of the viscometer and measure the resistance (torque).

3. Based on a verified resistance curve, a numerical value is calculated as the viscosity of the liquid, taking the rotation speed and torque as the factors.

Simply put, the instrument manufacturer converts the torque into viscosity on the basis of their data saying “The viscosity of a liquid, in which such a torque is generated when this rotor rotates at a speed of △△, is ◎◎!” This principle is common to the old spring-suspended analog type and the newest strain-detecting digital type.

You have to select the rotor and rotation speed

when using a viscometer.

Here, there are two points you need to care.

Point 1. To select the rotor and the rotation speed means to determine the “shear rate” during measurement.

If you have actually experienced the measurement, you probably know that the viscometer is supplied with several rotors. And, you can select some rotation speeds within the resistance range of each rotor. In short, to select the rotor and the rotation speed means nothing other than to determine the “shear rate” during measurement.

For Newtonian fluids such as starch syrup, viscosity does not depend on the shear rate, so theoretically constant regardless of conditions. However, as we explained in the previous session, the measured viscosity of a Non-Newtonian fluid inevitably varies depending on what type of rotor and what rotation speed you have selected.

Then, which viscosity is the true viscosity?

The answer is that each viscosity is true at each shear rate. This is the reason why the viscosity of Non-Newtonian fluids is called “apparent viscosity”. Accordingly, it is customary to show the apparent viscosity together with the measuring conditions, as shown in bold below.

Apparent viscosity of liquid = ◎◎ Pa・s

(Viscosity at a liquid temperature of ◇◇℃ measured using a ×× type rotational viscometer by rotating the No. ** rotor at △△ rpm)

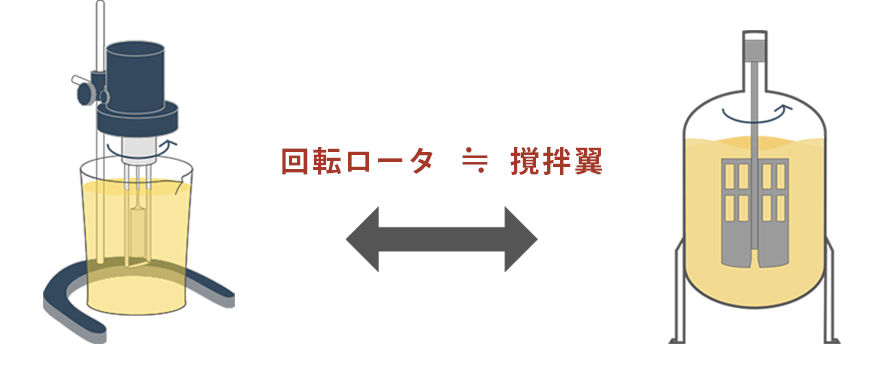

Point 2. Isn’t the consumption power of a mixing vessel similar to the rotation resistance of a viscometer rotor?

As explained above, a viscometer calculates viscosity from the resistance of a rotating rotor.

Isn’t it theoretically same as the consumption power of the actual mixing vessel ?

For viscometers:

Type of rotor x Rotation speed => Torque => Viscosity

For mixing vessels:

Type of impeller x Rotation speed => Torque => Power

Estimate the viscosity change of liquid form the rotation speed and consumption power of the mixing vessel.

That means...

Yes! You can estimate the viscosity change of a liquid in the mixing vessel in operation by monitoring the rotation speed and power consumption of the vessel.

It is impossible to measure the viscosity of polymer liquid under polymerization at 300℃ and 50 atm using a laboratory viscometer, but as long as you are conscious that the mixing vessel is a huge rotational viscometer for high-temperature, high-pressure fluids, you can estimate the viscosity during reaction from the consumption power change.

Furthermore, merely by slightly changing the rotation speed of the mixing vessel in operation and monitoring the power change, you can obtain much information about the liquid being mixed, such as whether the liquid is Newtonian or Non-Newtonian, whether the flow is turbulent or laminar, and whether there are baffle plates or not.

Even without going back to the office and doing massive fluid analysis, you can make a diagnosis by tapping a calculator on the spot to perform basic arithmetic operations.

By how quickly you can make such a diagnosis, you can show your skills as a mixing engineer. Let us disclose the secret to doing so in the next session.

-

Mixing Course

Beginner

course -

- Introduction Basic terms of mixing

- Course 1 Basics of basics: Three points to understand mixing

- Course 2 Examples of the purposes of mixing

- Course 3 Viscosity is the unit of stickiness

- Course 4 Consider a mixing vessel as a huge viscometer

- Course 5 Can you see the flow from power change? (Part 1)

- Course 6 Can you see the flow from power change? (Part 2)

- Course 7 Learn the essence of the mixing Reynolds number

- Course 8 Basics of basics of scaling up

- Course 9 Basics of scaling up

- Course 10 What is heat transfer performance in a mixing vessel?

- Course 11 What is film heat transfer coefficient , hi?

- Course 12 Mixing course review

-

Mixing Course

Practical

course -

- Introduction Mixing course SEASON II

- Course 1 Immediately determine the basic specifications of the mixing vessel using three pieces of information: operating liquid volume, viscosity and density.

- Course 2 Find a plan to improve the productivity of the mixing tank on the existing production line! (Part 1)