Products & Solutions Plant Engineering

Integration of core technology and engineering solutions

We propose our best performance for chemical industries with integration of our engineering solution and our core technologies such as mixing process, reaction process and distillation process, those are substantiated with our several decades career in the plant engineering fields.

We perform best engineering services at any phase from initial planning of chemical plant through detail design, construction, maintenance services for pilot plants, commercial plants etc.

EPC business

- E Engineering

- P Procurement

- C Construction

- A After service +

01 Planning Abundant experience

Sumitomo Heavy Industries Process Equipment(SHI-PE) provides engineering capabilities based on the technology and experience accumulated over many years.

02 Basic design Advanced engineering support

SHI-PE delivers high quality basic design so as to maximize the customer’s own know-how.

03 Detailed design Wide range of technical skills

SHI-PE has design specialists in equipment, piping, instrumentation, electricity, and architecture. And SHI-PE has capability to harmonize and unite these resources.

04 Procurement and manufacturing Superior manufacturing skill and quality control

SHI-PE procures and/or manufactures equipment by making the best use of the Sumitomo Heavy Industries network.

05 Construction Prominent capability in project execution

As construction professionals with abundant experience, SHI-PE staff members manage and execute project quality, deadlines, and safety.

06 Commissioning Unsurpassed capability in plant coordination/operation

SHI-PE assists to optimize plant operation though extensive experience.

07 After service Substantial after service

SHI-PE proposes excellent maintenance and plant evaluation.

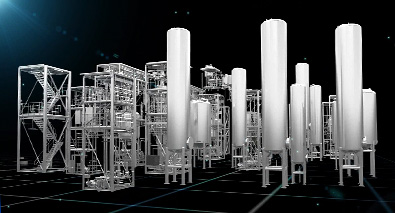

What is the modular construction method ?

The modular construction method means that instead of building the foundation at the customer's factory, the modules are manufactured in units of modules at our factory and then transported to the site for assembly.

This method minimizes the amount of on-site work.

STEP 01 Our Factory

- Production, assembly, and quality control by module

- Trial operation at our factory

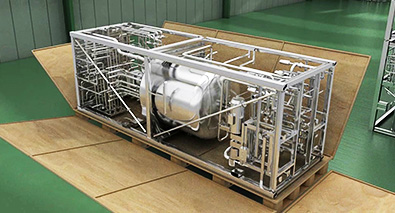

STEP 02 Transport

- Dismantling and transportation by module

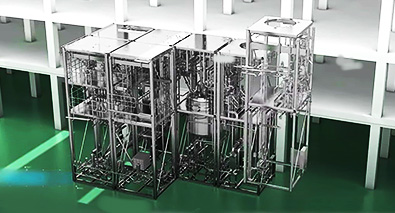

STEP 03 Customer's Factory

- Block erection by module

- Trial operation at customer's factory

Expected Effects

01 Minimizing project risks

- Risk of natural disasters and weather deterioration at on-site

- Rising labor costs and worker shortages at on-site

- Performance problems that emerge after on-site installation

- Process delays due to investigation, correction, and re-testing

- Safety risks associated with the use of fire in on-site construction

02 Shortened on-site construction period

- Parallel progress of foundation work and factory assembly

- Shortened on-site trial operation, early start-up

03 Proactive project planning and execution

- Simplified WBS

- Easy risk control because factory processes are the main focus

- Minimize cost and process buffers associated with project risk reduction

- Simultaneous achievement of low cost and customization through mass customization