Course 2

Examples of the purposes of mixing

Course 2

Examples of the purposes of mixing

How did you find the previous session "Understand the purpose of mixing"?

Now, in this session, we consider examples of the purposes of mixing. You will understand the importance of setting a goal.

A mixing vessel is full of unit operations

Inside any operating mixing vessel, there are always some of the unit operations (a chemical engineering term) such as reaction, mixing, dispersion (suspension), solution, precipitation, heat transfer, extraction, evaporation, and distillation.

In a crystallization operation with reaction heat, for example, reaction, precipitation, suspension, and heat transfer occur in order or simultaneously.

For chemical plant devices such as the stacked heat exchanger, distillation column, and extraction column, their names represent their target unit operations, and therefore, their purposes are easy to understand. For the mixing vessel, on the other hand, the name represents its means, and this is probably the reason that its purpose is difficult to understand.

Roughly speaking, when you are asked what the purpose of the mixing is, you can consider that what the person in charge thinks is the most important unit operation is the purpose.

Once you determine the purpose, you will naturally be clear about necessary features to make the mixing vessel optimal, as well as about the factors to be considered at the time of scaling up.

To choose the key operation from multiple factors

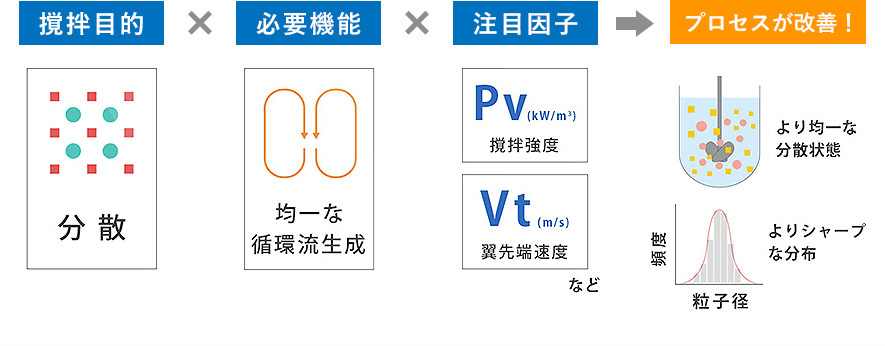

Now, let's have a quick look at purposes, required features, and notable factors in an example case.

Case:

Want to control the size and size distribution of polymer particles generated by emulsion and suspension polymerization

In this process, you disperse monomer liquid in the mother water in a mixing vessel to form oil droplets, and polymerization takes place in the oil droplets. The heat generated by polymerization is transferred by the mother water from the oil droplets surface, so that the process is stable in terms of temperature.

In the mixing vessel, dispersion, reaction, and heat transfer take place simultaneously, but if you want to control the particle size, the most important unit operation is dispersion. This is because, if you can realize uniform dispersion by mixing, you can control the particle size and its distribution. Thus, the purpose of the mixing vessel is uniform dispersion of liquid droplets and uniform dispersion particles.

Next, let's think about the features required for the mixing vessel to achieve the goal. In this case, the required feature of the mixing vessel is the generation of uniform flow circulating everywhere inside the mixing vessel without locally strong shearing, which is achieved by the optimization of the mixing impeller shape, rotation speed, and baffle plate.

As for notable key factors for scale-up, the mixing intensity Pv (kW/m3) and the impeller tip speed Vt (m/s) can be considered. It goes without saying that realizing the targeted particle size and particle size distribution will improve the quality and yield of the product.

Assessment of the purpose, the function and the factor leads to improvement of the quality and the productivity

If you are an engineer, consider the following three points about the mixing vessels in the manufacturing plant of your company.

1.What is the purpose? (i.e. What is the most important unit operation?)

2.What are the features required for the purpose?

3.What are the noteworthy factors?

You may find new points for improvement.

-

Mixing Course

Beginner

course -

- Introduction Basic terms of mixing

- Course 1 Basics of basics: Three points to understand mixing

- Course 2 Examples of the purposes of mixing

- Course 3 Viscosity is the unit of stickiness

- Course 4 Consider a mixing vessel as a huge viscometer

- Course 5 Can you see the flow from power change? (Part 1)

- Course 6 Can you see the flow from power change? (Part 2)

- Course 7 Learn the essence of the mixing Reynolds number

- Course 8 Basics of basics of scaling up

- Course 9 Basics of scaling up

- Course 10 What is heat transfer performance in a mixing vessel?

- Course 11 What is film heat transfer coefficient , hi?

- Course 12 Mixing course review

-

Mixing Course

Practical

course -

- Introduction Mixing course SEASON II

- Course 1 Immediately determine the basic specifications of the mixing vessel using three pieces of information: operating liquid volume, viscosity and density.

- Course 2 Find a plan to improve the productivity of the mixing tank on the existing production line! (Part 1)