Products & Solutions Coke Drum & Pressure Vessels

- HOME

- Products & Solutions

- Coke Drum & Pressure Vessels

We provide high-quality pressure vessels

worldwide, mainly on coke drums.

We respond to a wide range of customer needs by the establishment of a high level of quality assurance

system using structural design and manufacturing technologies based on our abundant experiences

and accomplishments.

Additionally, we offer inspection, assessment and welding repair services.

Features

- Highly durable coke drums.

- Reactors using low-alloy steels and materials requiring high-level welding.

- High-quality, ASME-certified pressure vessels.

- Comprehensive support, including design, manufacturing and assessment.

- Technological development and proposal to improve durability.

- Remaining life assessment by numerical analysis.

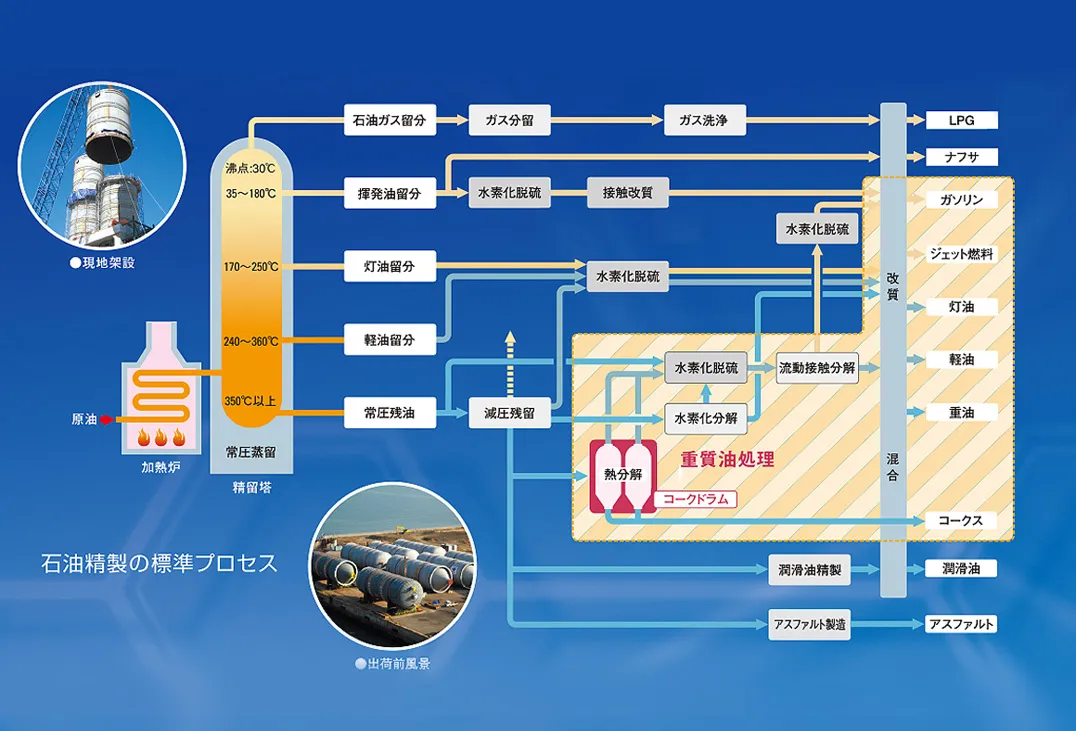

Standard oil refining process

- Dimensions

- 3,970 ID × 31,920 L

- Plate thickness

- 140.0 mm

- Material

- SA387-22-2+TP347 overlay

- Dimensions

- 12,000 ID × 37,350 L

- Plate thickness

- 49.0 mm

- Material

- KD63-M

- Dimensions

- 3,950 ID × 71,120 L

- Plate thickness

- 41.0 mm

- Material

- SA387-22-1

- Dimensions

- 5,000 ID × 36,420 L

- Plate thickness

- 39.0 mm

- Material

- SA240-TP340H

- Dimensions

- 4,370 ID × 32,720 L

- Plate thickness

- 19.0 mm

- Material

- SA516-GR70/SA240-TP304H

Factory and major facilities

Saijo Factory

- Land Area

- 535,000 m2

- Floor Space

- 48,000 m2

We manufacture large pressure vessels that are approved by ASME and various regulations. Our technologies allow for the welding of extremely thick materials and other such special materials.

By applying our large scale canning machine and welding technology, which we have developed through bridge engineering, we fabricate large steel structures with reliable manufacturing.