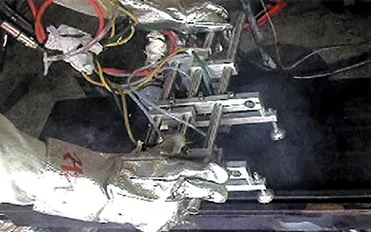

TOFD inspection while equipment is running using a high-temperature probe and contact medium.

About Us Factory & Major Facilities

01 Saijo Factory

We manufacture large pressure vessels that are approved by ASME and various regulations. Our technologies allow for the welding of extremely thick materials and other such special materials.

By applying our large scale canning machine and welding technology, which we have developed through bridge engineering, we fabricate large steel structures with reliable manufacturing.

- Land Area

- 535,000 m2

- Floor Space

- 48,000 m2

160-ton tower jib crane

320 tons / 2 machines

150-ton welding positioner

Maximum loading capacity: 150 ton

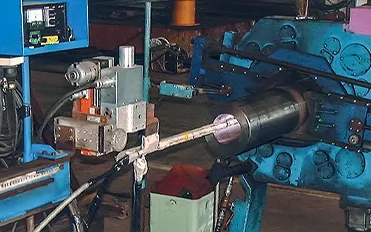

Bending roller

Maximum thickness: 100 mm

1

1

2

3

4

5

1

1

2

3

4

5

Vertical Lathe

Maximum table radius: 13 m

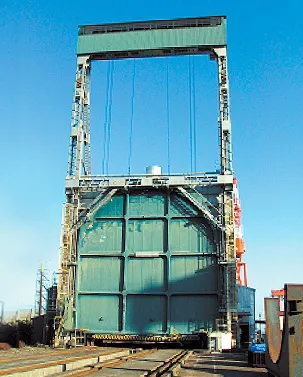

Annealing furnace

12 m (W) x 12 m (H) x 25 m (L)

02 Technological Development & Welding Technology

-

High-temperature TOFD flaw detection test

-

Scanner for inspection while code drum is running

Automatic ultrasonic test system that can be used even while the equipment is operating.

-

Wide weld overlay by ESW

-

Highly difficult weld deposit overlay using special materials.