Mixing Vessels SUPERBLEND

- HOME

- Products & Solutions

- Mixing Vessels

- SUPERBLEND

SUPERBLEND cleared an inconsistency between the laminar flow and turbulent flow using the 2-shaft mechanism.

Multipurpose mixer that exceeds the limitation of the vertical-type mixing vessel.

The homogeneous mixing from low viscosity to high viscosity, which was a critical issue of the mixing vessel, was attained by the 2-shaft mechanism with different impeller shapes. This mechanism always offers the optimum operations for an abrupt change of viscosity that is caused at multiproduct production or polymerization.

What is SUPERBLEND ?

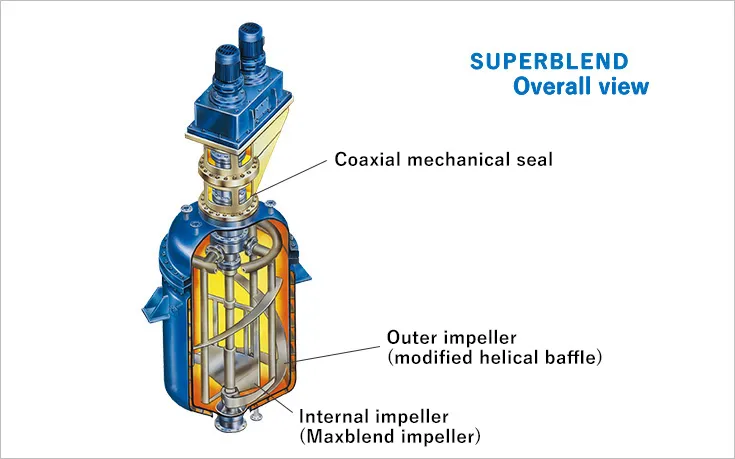

CHECK POINT 01 Structure

Vertical-type mixing vessel that has two coaxial mixing shafts equipped with the MAXBLEND impeller (inside) and helically-deformed baffle plate (outside).

CHECK POINT 02 Mixing mechanism

- 01 Combination of discharge and shearing functions

- SUPERBLEND provides both the discharge and shearing functions by placing the mixing vessels that have different mixing characteristics for the inside and outside.

- 02 Following-type change of mixing function depending on a change of viscosity

- The main function of the entire mixing is changed by an interaction depending on the viscosity environment, offering the appropriate mixing performance in a wide viscosity range.

| Low-viscosity area | High-viscosity area | |

|---|---|---|

| (Inner impeller) MAXBLEND |

Main mixing function Generation of discharge and circulating flows |

Prevention of flow stay in center of vessel Boost-up of circulating flow |

| (Outer impeller) HELICAL BAFFLE |

Baffle plate action Scraping on inner wall surface |

Main mixing function (Vertical mixing) Scraping on inner wall surface |

CHECK POINT 03 Features of SUPERBLEND

- 01 Applicable area in wide viscosity range

- Differences between turbulence flow and laminar flow, that was an issue in the previous models, have been cleared by different mixing characteristics of the inner and outer impellers.

SUPERBLEND offers continuously excellent mixing performance in a wide viscosity range of 1 to 10,000 poise or more.

- 02 Smooth support of abrupt change of viscosity

- The mixing functions of the inner and outer impellers run flexibly to suit a change of viscosity in the vessel, thereby, ensuring the appropriate flowing following an abrupt change of viscosity during reaction.

- 03 High temperature uniformity

- The stable flow speed is ensured on the wall surface and in the center of the vessel by the synergistic effect of the inner and outer impellers, offering the high uniformity in temperature. This feature significantly reduces a degradation of the polymer quality in the heat-spot.

- 04 Formation of powerful suction flow in gas-liquid interface

- A low-viscosity fluid sliding or staying phenomenon on the high viscosity fluid interface, which is an issue in the DOUBLE HELICAL RIBBON baffle of the previous model, is resolved, thereby, realizing a significant enhancement of a dispersion of reflux fluid and polymerized addition agents.

- 05 Appropriate slurry suspension

- Fouling or aggregates detected on the vessel wall or baffle plate during high-concentration of slurry operation, which are issues in the fixed-type baffle, have been resolved by using the mobile-type helical baffle.

- 06 Reduction of attachment amount in vessel

- The stable wall-surface flow speed is ensured by the outer impeller that rotates adjacently the inner wall of the vessel, thereby, reducing fouling on the inner wall and significantly decreasing the inside washing time and count.

CHECK POINT 04 Use applications

- Massive or solution polymerization reaction

- Polycondensation reaction

- Monomer removal and desolventizing operations

- High-concentration of slurry and

high-concentration of crystallization operations - Powder and resin dissolution operations

CHECK POINT 05 Characteristics of SUPERBLEND, Co-axial Vertical Mixing Vessel

In this paper, you can easily understand about the structure and features of "SUPERBLEND", a co-axial vertical mixing vessel stable uniform mixing performance in a wide range of liquid viscosity.

Product introduction Movies

Multi-purpose mixing equipment exceeding the limits of the applicable range of viscosities.

Coaxial dual mixer consisting of MAXBLEND for the inner impeller and helical ribbon for the outer impeller.

Two different types of impeller are combined by a concentric coaxial mechanism to extend the viscosity region of liquid to treat.

In this movie, you can easily understand the mixing mechanism and features of SUPERBLEND.

CHECK POINT 06 Introduction of test equipment

SUPERBLEND test equipment specifications

- Capacity

- 22L

- Design pressure

- F.V to 6kg/cm2G

- Design temperature

- 350℃

- Major dimensions

- φ310mm×650TLmm

- Material

- SUS 316L

- Drive

- Inverter

- Inner impeller

- 2.2kW N=11~194rpm

- Outer impeller

- 2.2kW N=3~41rpm

- Shaft seal

- Double mechanical seal

* With drive lifting device

INFORMATION Related Information

-

Plant Engineering

Plant Engineering

We propose our best performance with integration of our engineering solution and our core technologies, those are substantiated with our several decades career in the plant engineering fields.

-

Technical Services

Technical Services

It is possible to obtain test data under any operating conditions using many kind of test facilities.

So, we will can evaluate and propose optimum mixing power as well as equipment specification for scaled-up or scaled-down model. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.