Mixing vessels Technical Services

- HOME

- Products & Solutions

- Mixing vessels

- Technical Services

-

Production process

improvement -

Customized to optimal

specifications -

Performance confirmation

before purchase

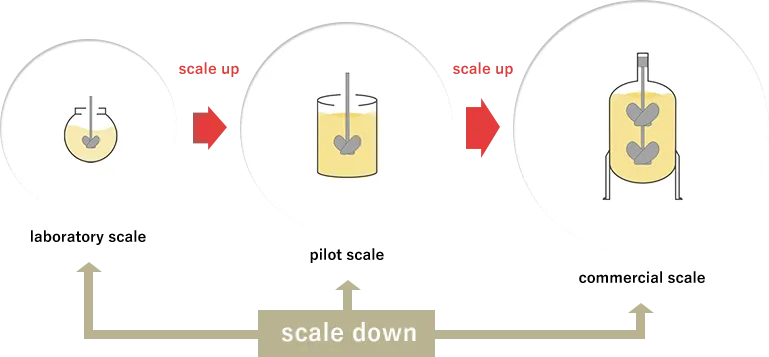

Data acquisition and performance check are available for all processing capacity from laboratory scale to commercial scale of equipment.

Engineers of Sumitomo Heavy Industries Process Equipment, experts of mixing,

will help you with the improvement of the mixing process,

the establishment of a new process, and performance comparison tests.

We will propose an optimum solution tailored to your agenda. Feel free to consult us.

STEP!! for Mixing Equipment Optimization

General study steps to determine

optimal specifications

for mixing equipment

-

STEP 01 Consultation

Please tell us about your current problems and what you want to improve.

We will confirm "current problems and issues" and "the purpose of mixing".

-

STEP 02 Exploring Factors

We will explore "current problems and issues" based on our clients' and our own experience.

-

STEP 03 Development of Countermeasures

Narrow down factors in consideration of priorities and formulate countermeasures.

Estimate and schedule confirmation

-

STEP 04 Review and Verification

of Proposed CountermeasuresThe measures we have developed will be verified in one or more of the following areas.

Specific Verification DetailsDesk Review

Verification based

on our past experience.- Consideration of mixing power

- Setting up mixing power to fit the purposes, selection of motor capacity

- Consideration of heat transfer performance

- Calculation of temperature rise time in mixing vessel

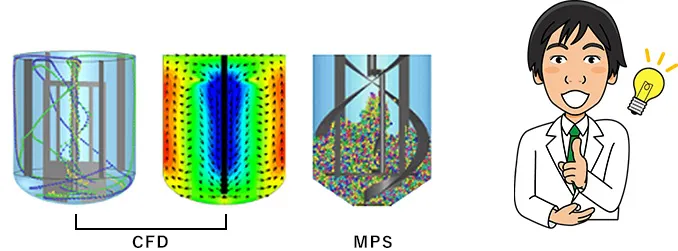

Simulation

Verification by

general-purpose thermal hydraulics

analysis software・Flow, Concentration, Heat transfer

Test Impeller Fabrication Service

Verification with your existing

mixing vessel or with

a material difficult to take outThis service creates a custom-order mixing impeller that suits the testing conducted with your own mixing vessel or with a material that is difficult to take outside your company.

We will propose an impeller shape that suits your process, and deliver a custom-order impeller together with a power curve chart.Supported vessel capacities: 3 to 1000 L

Delivery: Approx. one monthTest Device Rental Service

Verification with mixing equipment

under real-life conditionsSumitomo Heavy Industries Process Equipment have rental devices for testing.

We provide a variety of devices including NANOVisK, a hybrid mixing device that realizes the nano range of droplets in emulsion, and MAXBLEND, whose unique impeller shape exercises ground-breaking mixing characteristics.Visiting Test

Verification through

visualization tests tested

by mixing expertsVisit us to conduct the test. You will use our experimental facilities with the attendance of a specialized engineer who help you collect data necessary to determine the specification of mixing type of reactors including a separable flask and a production machine.

We also provide various types of impellers and internal devices.Examples of tests

- Mixing test

- measuring the decolorization time and optimum mixing power and observing stagnant one using a simulated liquid

- Solid-liquid suspension test

- easuring the local slurry concentration and the critical suspension power

- Gas dispersion test

- measuring kLa and gas holdup

-

STEP 05 Optimal Proposal for Mixing Equipment

- Based on the above verification results, we will propose an optimized mixing system to solve your problem.

- 《Proposal Items》

- Required mixing power, Motor rated capacity, Heat transfer, Complete mixing time, Mixing impeller,

Presence and shape of jacket and internals

- Submission of report and experimental results

- Proposal of actual equipment specifications

- Based on the above verification results, we will propose an optimized mixing system to solve your problem.