Mixing Vessels LvBLEND

- HOME

- Products & Solutions

- Mixing Vessels

- LvBLEND

Realization of high subdivision performance in a more compact drive unit.

Original impeller with an inclined circular arc shape.

High shearing is produced for low viscosity or liquid-to-liquid mixing.

Multistage operation is performed using the optimal impeller diameter and inclination angle depending on mixing needs.

Features of LvBLEND

- Has a compact size (low torque) (Reduces initial costs and running costs.)

- Reduces running time thanks to a high shearing function (Enhances productivity and improves yield.)

- Contributes to improved product quality (Lump-free and high-quality product finishing.)

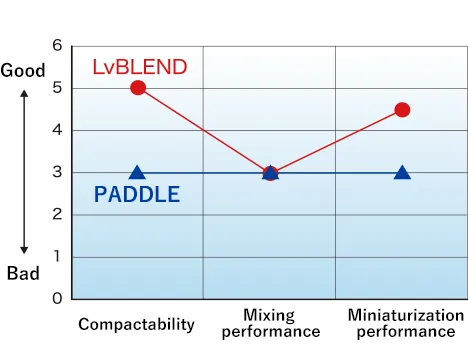

CHECK POINT 01 Comparison with paddle

LvBLEND is an impeller with excellent refinement characteristics while maintaining mixing performance equivalent to the conventional paddle.

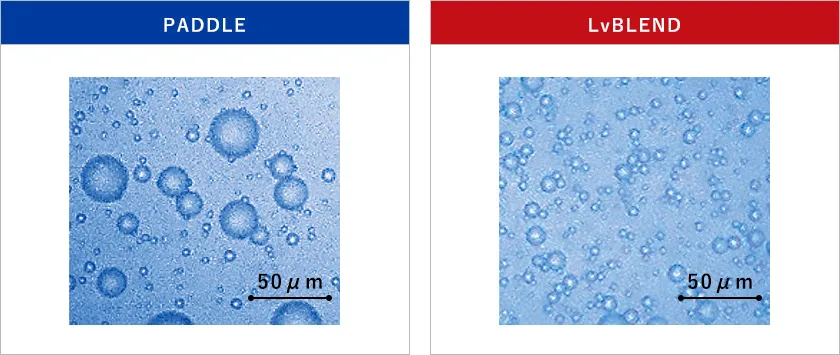

CHECK POINT 02 Comparison of droplet refinement performance

LvBLEND has better droplet refinement performance than the conventional paddles thanks to the high shearing effects.

[Test condition]

- Oil phase volume fraction: 1vol %

- Agitation for 20 min. with constant power

INFORMATION Related Information

-

Plant Engineering

Plant Engineering

We propose our best performance with integration of our engineering solution and our core technologies, those are substantiated with our several decades career in the plant engineering fields.

-

Technical Services

Technical Services

It is possible to obtain test data under any operating conditions using many kind of test facilities.

So, we will can evaluate and propose optimum mixing power as well as equipment specification for scaled-up or scaled-down model. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.