Products & Solutions

Distillation &

Liquid-Liquid Extractor

- HOME

- Products & Solutions

- Distillation & Liquid-Liquid Extractor

Product Line up

-

01 Item list Structured packing

Our SFLOW, structured packing, exhibits excellent separation performance over a wide range of process, from low liquid throughput to high liquid throughput due to special surface treatments and its unique structures.

We supply two types of SLOW, sheet-type and wire-netting-type. And there are 9 types for sheet-type and 2 types for wire-netting, depending on the specific surface area and corrugated plate angle.

We offer appropriate type for the best solution.-

Structured packing SFLOW sheet type

Widely applied to various kinds of processes, basing on our abundant experiences.

-

Structured packing SFLOW Wire-netting type

Applied to high performance separation process.

Sometimes this type is applied to revamping project such as upgrading from sheet-type.

-

-

02 Item list Tray

-

Tray

We provide various trays as well as the packed column.

-

-

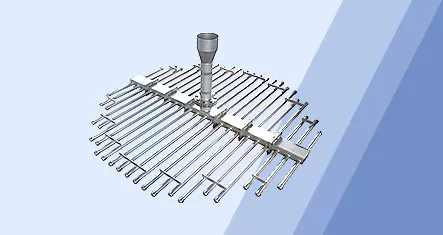

03 Item list Internal

For SFLOW performance, it is also important to select optimal collector and distributor which distribute the process liquid uniformly and efficiently.

We will propose optimal combination of the various structured packings, the various distributors and collector laminar.-

-

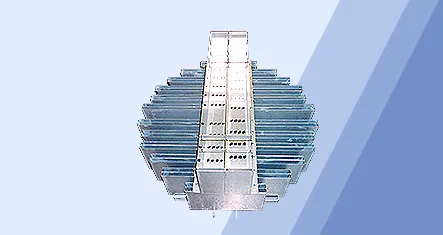

Internals for packed column Distributor

(Channel type) -

Internals for packed column Distributor

(Tubular type)

Distributor that affects the performance of the packed column.

We propose, design and manufacture the optimum distributor to suit the required turndown ratio or liquid properties. -

-

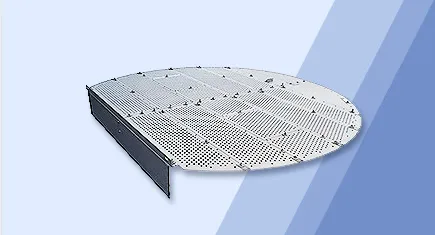

Internals for packed column Collector laminar

Liquid collection and re-distribution in the column are required to ensure the stable performance of the packed column.

This collector laminar, which features a low-pressure drop structure, is used to collect liquid.

-

-

04 Item list Distillation column

We offer solutions for distillation plant with our distillation technologies, optimizing packed column with structured packing, random packing and/or tray column.

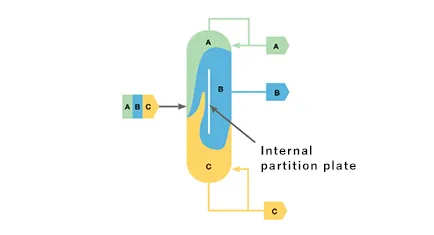

Recently we highlight the energy-saving distillation column, Column-In-Column, known as DWC or Divided Wall Column for the multicomponent separation process, and increase its deliveries.-

Column-in-column

Conventionally multiple columns are required for multi-component separation process.

In response, we have developed a next-generation distillation system for multicomponent separation process. This system decreases energy, space, piping-work, instrumentation etc, and accordingly reduce both initial and running costs. -

Columns

Columns, Re-Boilers and Condensers are the main equipments for distillation process and derive the excellent performance of SFLOW structured packing, trays and random packing. We have abundant design and manufacturing experience for various code and non-code products and control those quality.

We propose the optimal reboiler and condenser depending on our vast experience for various processes. -

FFPLUS

FFPLUS is an attachment for falling film type reboiler.

FFPLUS reduces the thermal entrance region of heat exchanger tube and contributes to utilize the performance of heat exchanger effectively.

FFPLUS can be attached to the existing equipment as well as to newly installed equipment, and retrofit the existing equipment.

-

Plant Engineering

SHI-PE provides total engineering support for all phases of project execution,from planning to after service.

We perform best engineering services at any phase from initial planning of chemical plant through detail design, construction, maintenance services for pilot plants, commercial plants etc.

Technical Services

We support the study of distillation process and/or propose process improvement at the initial planning stage or basic design stage.

We can offer various services, such as process proposal with process simulator and pilot plant test with actual process liquid etc.

Energy Conservation Measures

The distillation process consumes about 40% of the energy in the chemical industry.

Energy conservation in distillation facilities is one of the most urgent issues to realize a decarbonized society.

We propose equipment and energy-saving technologies that match the characteristics of the manufacturing process and materials handled, including economic efficiency.