Products & Solutions Offshore Wind Foundations

- HOME

- Products & Solutions

- Offshore Wind Foundations

Advancing renewable energy to help achieve carbon neutrality

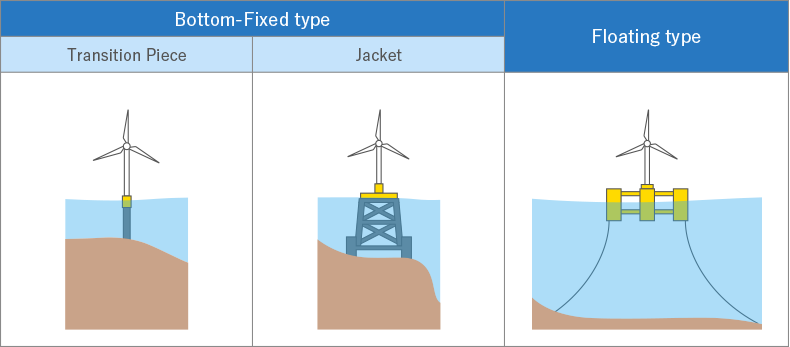

We use our advanced fabrication and welding technologies for extremely thick-walled cylindrical structures, developed through manufacturing pressure vessels and steel structures, to produce foundation structures for offshore wind power generation facilities, such as transition pieces, jackets, and floating foundations.

Features

- Capabilities in creating extremely thick cylindrical structures, honed over 50 years in manufacturing pressure vessels and steel structures

- Advanced quality assurance systems and process management capabilities

- World-class factory facilities with expansive grounds used for manufacturing and storage yards

About Offshore Wind Power Generation

Offshore wind power generation involves installing wind turbines at sea to generate electricity. It converts wind energy into electrical energy without emitting CO₂ during power generation, making it a renewable energy source. While Japan’s land area is limited, its island geography offers great potential for offshore wind power generation, which is seen as a key solution for reaching carbon neutrality.

We manufacture foundation structures for offshore wind power generation facilities, including transition pieces and jackets, as well as floating structures.

Factory and major facilities

Saijo Factory

- Land Area

- 535,000 m2

- Floor Space

- 48,000 m2

We manufacture large pressure vessels that are approved by ASME and various regulations. Our technologies allow for the welding of extremely thick materials and other such special materials.

By applying our large scale canning machine and welding technology, which we have developed through bridge engineering, we fabricate large steel structures with reliable manufacturing.

Delivery record

We have manufactured the superstructures and legs of jacket-type foundations for offshore wind farms in Japan.

(Client:NIPPON STEEL ENGINEERING CO., LTD.)

-

Superstructures of jacket type foundation

-

Legs of jacket type foundation

Quality and Process Management

With our many years of expertise in manufacturing and compliance with various regulations, including ASME for pressure vessels, we implement advanced quality and process control to deliver high-quality products.

We offer a range of inspections, including non-destructive inspections such as PAUT (Phased Array Ultrasonic Testing) and TOFD.

Efforts by the Sumitomo Heavy Industries Group

We collaborate with Sumitomo Heavy Industries Marine & Engineering Co., Ltd. to leverage synergies as part of the Sumitomo Heavy Industries Group. We will further strengthen our mass production system.