Mixing Vessels MAXBLEND

- HOME

- Products & Solutions

- Mixing Vessels

- MAXBLEND

Providing innovative mixing features generated by the unique impeller shape.

MAXBLEND (which generates ideal flow that cannot be realized with other impeller models) consists of the bottom paddle and the upper grid.

Functional Lineup to Meet User Needs

We design and offer the optimized MAXBLEND impeller shape suited to your needs using our highly developed and diversified processes.

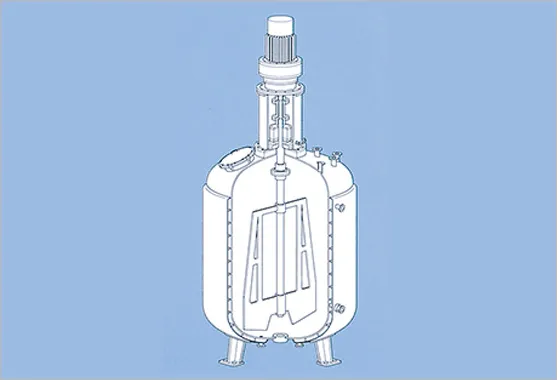

M/B-W type For high viscosity fluid mixing MAXBLEND

Even if high viscosity is advanced, a primary circulating flow with a high peak is formed, enabling uniform mixing in the vessel.

During actual operation, a reduced secondary circulating flow (collateral circulation flow) results in effects such as a reduction of attached substances or abnormal reactants, or uneven heat transfer.

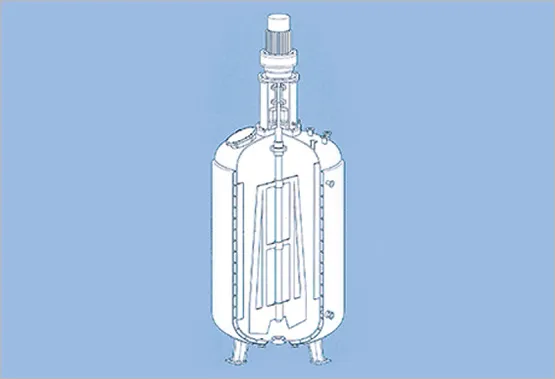

M/B-R type For high liquid depth MAXBLEND

This impeller circulates liquid in one flow, from the vessel bottom to the liquid surface, by up to 2.5 times the liquid depth of the vessel diameter ratio, enabling quick homogeneous mixing in the vessel.

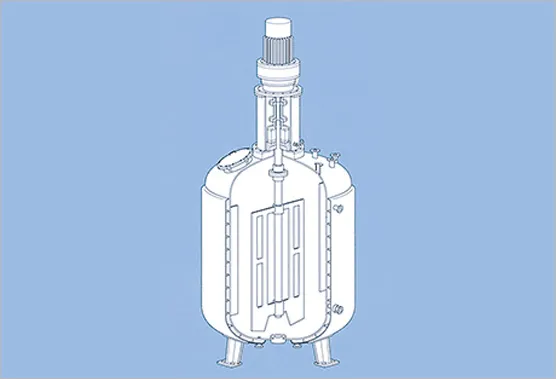

M/B-G type For aerated mixing MAXBLEND

This impeller realizes both high shear characteristics (to fine bubbles) and high circulation characteristics (for efficient gas hold-up), enabling a high level of gas absorbability that was impossible with conventional impeller models.

Development of "MAXBLEND" Specialized in Various Operations

This paper explains the basic characteristics and performance evaluation of high viscosity fluid mixing MAXBLEND (M/B-W type), high liquid depth mixing MAXBLEND (M/B-R type), and aerated mixing MAXBLEND (M/B-G type) using experimental data.

Bioreactor

Growing interest in the global environment and natural resources has led to more sophisticated research and development of biofuels and bioplastics in recent years.

We deal with mixing equipment for culture and fermentation, separation and refinement equipment, as well as sub-facilities for utilities, tanks, raw material handling etc.

Beakerscale, pilot plants, etc., please feel free to contact us regardless of the size of your project.

INFORMATION Related Information

-

Plant Engineering

Plant Engineering

We propose our best performance with integration of our engineering solution and our core technologies, those are substantiated with our several decades career in the plant engineering fields.

-

Technical Services

Technical Services

It is possible to obtain test data under any operating conditions using many kind of test facilities.

So, we will can evaluate and propose optimum mixing power as well as equipment specification for scaled-up or scaled-down model. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.