Mixing Vessels Bioreactor

- HOME

- Products & Solutions

- Mixing vessels

- MAXBLEND

- Bioreactor

Bioreactor

Growing interest in the global environment and natural resources has led to more sophisticated research and development of biofuels and bioplastics in recent years.

We deal with mixing equipment for culture and fermentation, separation and refinement equipment, as well as sub-facilities for utilities, tanks, raw material handling etc.

Beakerscale, pilot plants, etc., please feel free to contact us regardless of the size of your project.

CHECK POINT 01 Highly efficient culture and fermentation processes

By optimizing MAXBLEND with its excellent basic characteristics for culture and fermentation processes, we have developed a highly productive, compact, and energy-efficient bioreactor.

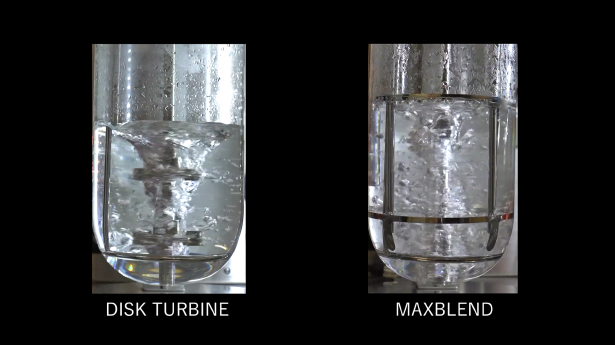

MAXBLEND bioreactors have lower shear force and better gas involvement performance (kLa) than reactors equipped with general disc turbine impeller, are superior for culture and fermentation of microorganisms because it is easier to control the culture medium to aerobic or anaerobic conditions.

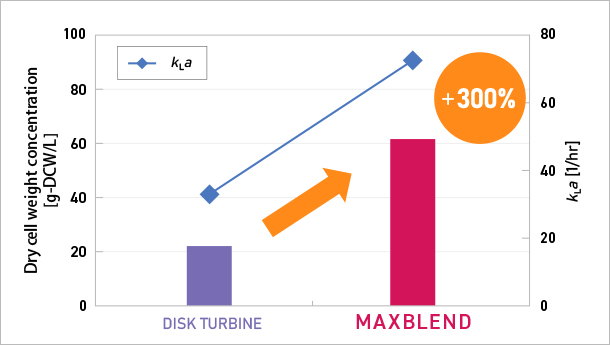

The graph shows the results of a fed-batch culture using Saccharomyces cerevisiae.

Under the same culture conditions, MAXBLEND bioreactors resulted in approximately 300% higher in dry cell weight concentration compared to conventional bioreactors using disc turbine impeller.

CHECK POINT 02 Technical services

We can assist you in performance comparison testing prior to purchase through the test impeller fabrication service, the test device rental service, and the visiting test service.

CHECK POINT 03 Custom-made

From laboratory scale to commercial scale of equipment.

Scale-up and scale-down at any throughput capacity.

We offer the best specifications according to various operating conditions.

CHECK POINT 04 Plant engineering

We deal with mixing equipment, separation and refinement equipment, as well as sub-facilities for utilities, tanks, raw material handling etc.

MAXBLEND Fermentor,

for High Viscosity Fermentation

This report mainly describes the results of the mixing performance test under aeration-mixing conditions and the biopolymer fermentation test conducted in a laboratory-scale fermentor.

INFORMATION Related Information

-

Mixing Vessels

Mixing Vessels

We offer a variety of mixing products, including MAXBLEND.

We can customize the equipment specifications to best suit your process. -

Distillation &

Distillation &

Liquid-Liquid ExtractorWe offer a variety of distillation products, including SFLOW.

We can customize the equipment specifications to best suit your process. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.