Mixing Vessels TORNADO

- HOME

- Products & Solutions

- Mixing Vessels

- TORNADO

Realization of the excellent mixing efficiency by reverse thinking

TORNADO is a high-depth and high-efficiency mixing vessel. The mixing mechanism, which provides innovative flow patterns flowing the wall surface from top to bottom, realizes excellent mixing performance in the long and thin mixing vessel in which homogeneous mixing is difficult significantly.

CHECK POINT 01 Mixing Performance

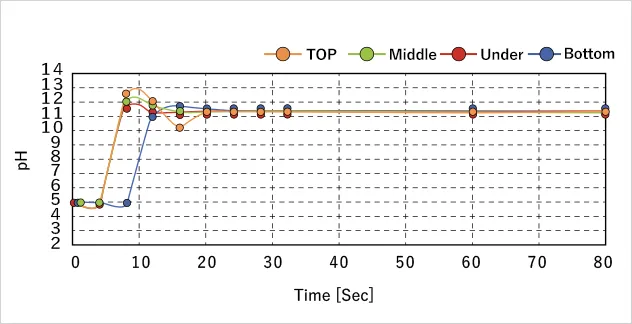

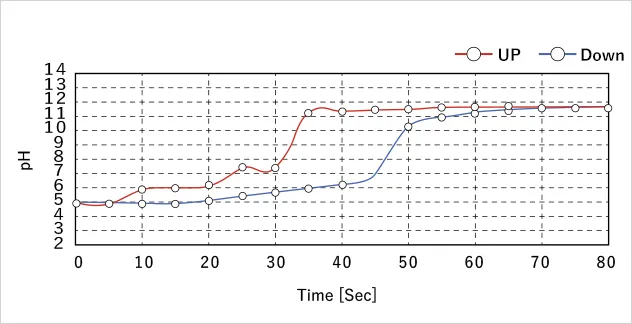

Comparison of mixing performance with liquid measure 25m3

The TORNADO offers the homogeneous mixing in a shorter time than the previous multistage impeller models by approximately 1/5.

The graph shows how the pH value is changed at four positions in the upper and lower sides of the wall surface when alkaline solution is put from the manhole of the upper mirror in the vessel while the real machine is running at water volume 25m3.

Using the TORNADO's innovative flow patterns, the time required to ensure the constant pH value in the vessel was reduced approximately 1/5 as compared with the previous multistage impeller models.

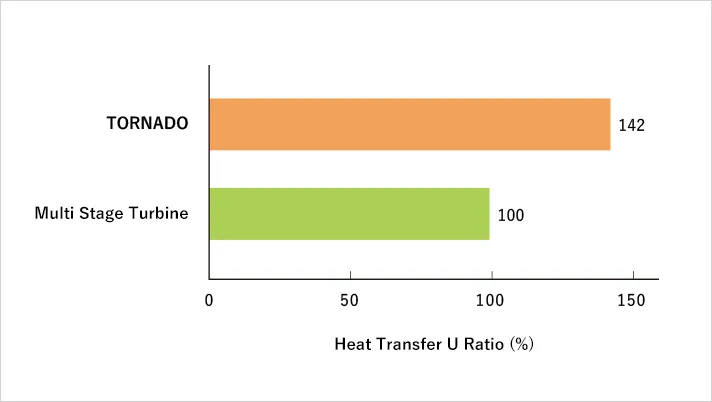

CHECK POINT 02 Heat transfer performance

Comparison of overall heat transfer coefficient, U value

The heat transfer performance has been enhanced significantly by the flow characteristics in the vessel.

The graph shows how the overall heat transfer coefficient, U value, transitions when a heat transfer is applied while the real machine is running at water volume 25m3.

For the new-model impeller, the U value is increased 30% or more as compared with the previous impeller models.

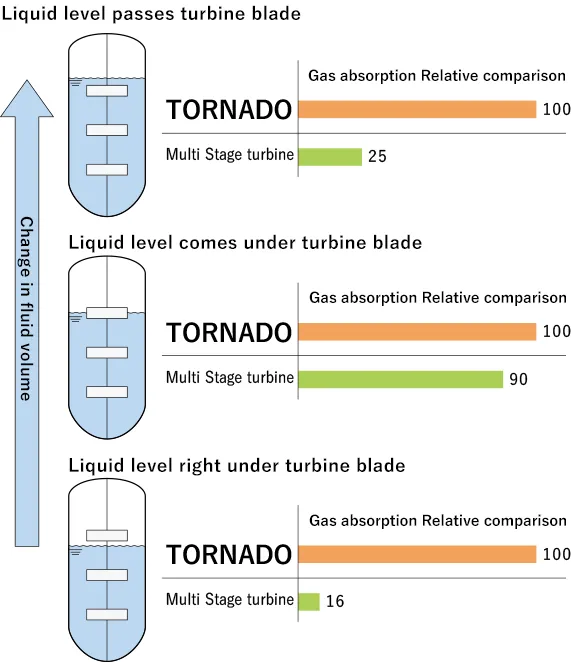

CHECK POINT 03 Gas absorbability

The graph shows the comparison of gas absorbability that is generated when liquid is involved from the gas phase in the test equipment (90L). For the new-model impeller, this result shows a higher gas absorbability than the previous impeller models. For the previous-model multistage impeller, the gas absorbability is unstable due to a variation of the liquid depth. For the new-model impeller, the stable gas absorbability is realized in high level even at the time of variation of the liquid depth.

INFORMATION Related Information

-

Plant Engineering

Plant Engineering

We propose our best performance with integration of our engineering solution and our core technologies, those are substantiated with our several decades career in the plant engineering fields.

-

Technical Services

Technical Services

It is possible to obtain test data under any operating conditions using many kind of test facilities.

So, we will can evaluate and propose optimum mixing power as well as equipment specification for scaled-up or scaled-down model. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.