Mixing Vessels BULLBLEND

- HOME

- Products & Solutions

- Mixing Vessels

- BULLBLEND

Achieve gentle and uniform flow

within the vessel with low power consumption!

BULLBLEND, a high-performance and compact impeller mixer, combines the excellent mixing capabilities of MAXBLEND

with the space-saving design of small impellers to achieve gentle, uniform flow within a vessel using low power.

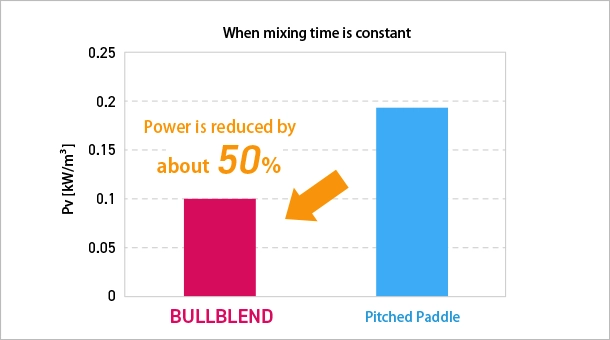

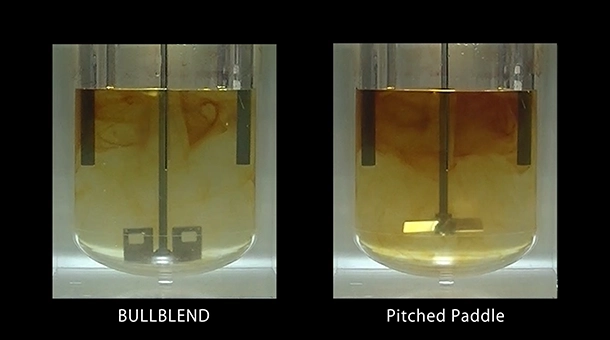

CHECK POINT 01 Excellent Mixing Performance

BULLBLEND can reduce power consumption by approximately 50% while maintaining the same mixing time as conventional systems, contributing to lower CO₂ emissions.

As a result, it is widely adopted in various processes such as crystallization, slurry discharge, and acid precipitation.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: 100cP, Liquid Volume: 21.6L, Baffles: 4 Flat Plates

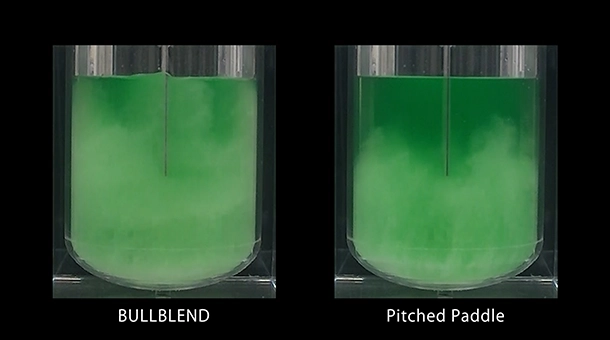

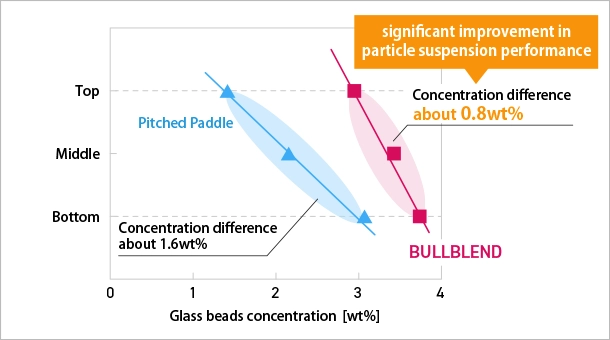

CHECK POINT 02 High Solid Dispersion Performance

When compared under the same power conditions, BULLBLEND significantly improves solid dispersion performance, enabling solid particles to be suspended even near the upper interface. As a result, vertical concentration differences are minimized, leading to a more uniform mixing state.

This is especially beneficial in processes involving solid-liquid mass transfer, where the transfer rate is enhanced, allowing operations such as dissolution to be completed in a shorter time.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: Approx. 1cP, Liquid Volume: 23.8L, Baffles: 4 Flat Plates, Particles: Glass (Diameter 350-500 μm)

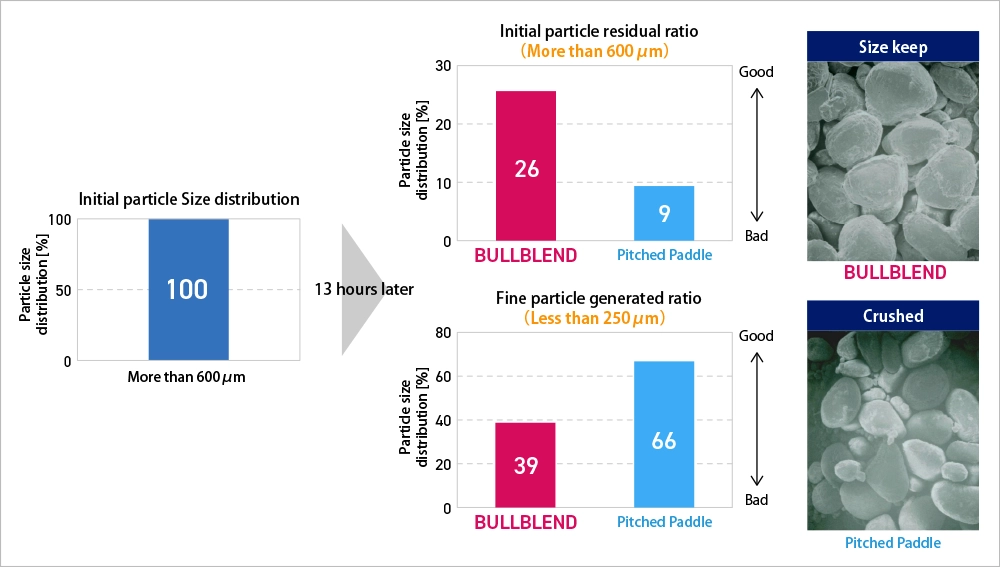

CHECK POINT 03 Low Shear Performance

The graph shows the results of a crystal fracture test using boric acid.

After 13 hours of mixing at the same power, BULLBLEND generated fewer fine particles than the inclined paddle impeller, confirming its capability for lower-shear mixing compared to small impellers.

Low-shear mixing suppresses the generation of fine particles and helps maintain the quality of precipitated particles, making it ideal for processes such as crystallization where particle breakage must be avoided.

【Mixing Conditions】

Tank Diameter: 310mm, Viscosity: Approx. 1cP, Liquid Volume: 26L, Particles: Boric Acid

INFORMATION Related Information

-

Plant Engineering

Plant Engineering

We propose our best performance with integration of our engineering solution and our core technologies, those are substantiated with our several decades career in the plant engineering fields.

-

Technical Services

Technical Services

It is possible to obtain test data under any operating conditions using many kind of test facilities.

So, we will can evaluate and propose optimum mixing power as well as equipment specification for scaled-up or scaled-down model. -

The more you learn the mixing, the more mysteries you find.

Sumitomo Heavy Industries Process Equipment, mixing specialist, will provide clear explanations on the basics of mixing techniques and how to select mixing devices.