Mixing Vessels Useful Clues for the Mixing Beginners Mixing Course

- HOME

- Products & Solutions

- Mixing Vessels

- Mixing Course

- Beginner course 1:Basics of basics: Three points to understand mixing

Course 1

Basics of basics: Three points to understand mixing

Course 1

Basics of basics: Three points to understand mixing

The act "mixing" is prevalent everywhere including everyday life and production sites.

Let's give a deep though on this "mixing"

Have you ever tried to mix water and flour using chopsticks and failed? What would you do in that case? Someone may try to stir quickly, and another may crush flour clumps one by one. Everyone would have their own ways.

Now then. What is actually the correct way of mixing?

You could use chopsticks to mix water and flour although it takes time. However, you will reach the goal more easily and quickly if you use a hand mixer. This means that you can increase efficiency by using a good method.

This also applied to "mixing" in general. There are cases also in large-scale production sites that just optimizing the existing mixing equipment can largely improve the productivity, cost, and quality. Is the mixing equipment of your production line really optimum for the process?

With this in mind, we will introduce three points as the first step of selecting an optimum mixing equipment.

Point 1:

Understand the purpose of mixing. What do you mix the materials for?

Mixing is the act of mincing and homogenizing "something" for "some purpose." Mixing itself is just the means.

You can call a washing machine or a juicer a "mixing equipment", and they have clear purposes: clean clothes and delicious juice.

Their names represent their purposes, so that everyone can understand their performance and effect.

However, devices that are called mixing equipment in the industrial world have a very wide range of purposes such as dilution, solution, emulsion, reaction, dispersion, heating, cooking, gas absorption, and so forth.

Therefore, when you select an industrial mixing machine, the first thing to do is to understand "for what you want to mix the materials" and set a clear goal.

Point 2:

Understand the things to be mixed. How does the material change by mixing?

Once you set the goal, the next thing to do is to clarify "what you want to mix."

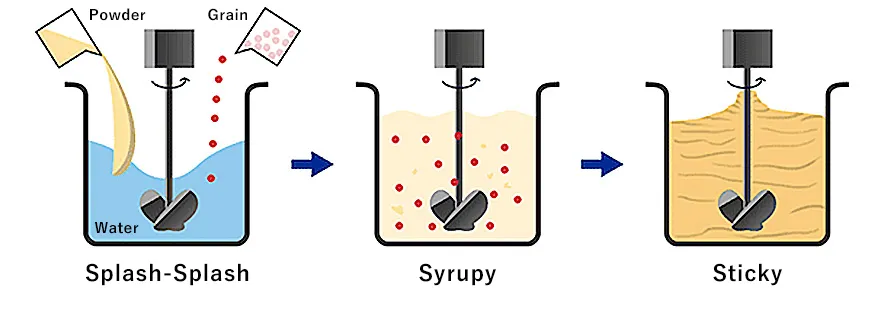

Imagine the things that you want to mix. For example, if the material is a liquid, is it like water or a sticky rice cake? In some cases you may want to mix in powder, or mix in gas like air supply into a fish bowl.

Let's imagine in further detail. How does the thing to be mixed change by mixing? Can you imagine that "it suddenly becomes sticky after some progress of reaction", "the liquid becomes like a stew when powder melts into it", or "the liquid becomes like whipped cream when it involves air?" Think of something close to you and imagine it.

If you can translate the image to values such as viscosity, density, concentration, particle size, gas flow, and so forth, then you have rulers to measure properties of the things that you want to mix.

and the change of material to be mixed

But in reality, the most difficult thing is to make rulers. It is true, especially in the food and cosmetics industries, that there are somethings that largely rely on the producer's skill and senses such as "the texture of the cream that a pastry chef makes" or "the luster and feel of a smooth beauty essence."

Point 3:

Understand the mixing environment. What are operation conditions? Are there any relevant regulations?

Finally, let's think about the environment (operation conditions) in which you want to conduct the mixing. The number one conditions to thing about are the amount, temperature, and pressure that are optimum for mixing the target material. These properties determine the specification of the vessel (tank).

We will explain the details in later chapters, but the specification includes whether the tank is open or closed, how the sealing mechanism of the shaft should be to prevent the content from leaking, and what the applicable regulations are for the tank of the process.

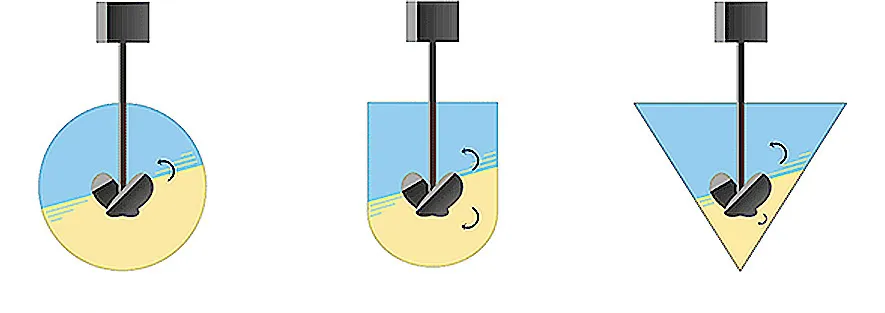

When mixing things, the shape and performance of the mixing impeller (paddle) are often considered, but there is another thing that you should not overlook. The thing is that the flow of the mixed material is determined by the combination of the mixing impeller, the shape of the vessel, and the internals (internal parts such as baffle plate, coil, etc.).

vessel and internals is important!

In other words, when you think of the performance of a mixing vessel, you must give a total consideration of "the size of vessel, the vertical position of the vessel at which to install the mixing impeller, and the required types of baffle plate and heat transfer coil." (See the image.)

The mixing impeller, the vessel, and internals are not separate things. You must ensure the safety in accordance with the applicable laws, and design a structure understand high-temperature high-pressure condition.

The most important element in selecting a mixing machine is "the total design of the mixing impeller, mixing vessel, and internals", in other words, "reactor engineering skills."

-

Mixing Course

Beginner

course -

- Introduction Basic terms of mixing

- Course 1 Basics of basics: Three points to understand mixing

- Course 2 Examples of the purposes of mixing

- Course 3 Viscosity is the unit of stickiness

- Course 4 Consider a mixing vessel as a huge viscometer

- Course 5 Can you see the flow from power change? (Part 1)

- Course 6 Can you see the flow from power change? (Part 2)

- Course 7 Learn the essence of the mixing Reynolds number

- Course 8 Basics of basics of scaling up

- Course 9 Basics of scaling up

- Course 10 What is heat transfer performance in a mixing vessel?

- Course 11 What is film heat transfer coefficient , hi?

- Course 12 Mixing course review

-

Mixing Course

Practical

course -

- Introduction Mixing course SEASON II

- Course 1 Immediately determine the basic specifications of the mixing vessel using three pieces of information: operating liquid volume, viscosity and density.

- Course 2 Find a plan to improve the productivity of the mixing tank on the existing production line! (Part 1)