Mixing Vessels Useful Clues for the Mixing Beginners Mixing Course

- HOME

- Products & Solutions

- Mixing Vessels

- Mixing Course

- Practical course Introduction:Mixing course SEASON II

Intoroduction

Mixing course SEASON II

Intoroduction

Mixing course SEASON II

In the Mixing Course for Beginners, we discussed the essence or vital points regarding the purpose of use, scale-up, power, heat transfer and so on of mixing vessels over 12 times. We subsequently received numerous requests from readers, such as "I would like to hear more practical stories about the basic design method and scale-up of the mixing vessels." To respond to these requests, we have established the Mixing Course SEASON II (Practical Course).

In this practical course, we will introduce ideas for optimizing mixing equipment by assuming more practical scenes at research and development and production sites, just as the title suggests. For example, "How do mixing vessel engineers determine the specifications of their mixing vessels?", "How are our customers, the users, planning production facilities based on laboratory experiment results?" and "What approach is being made to examine and improve the productivity of the existing facilities?"

We will also introduce some parts of a short story in an easy-to-understand manner where possible and make them fun to read. The story is about mixing vessel manufacturing staff who work with their customers to tackle a range of challenges every day and about a young engineer, the vessel user, who acts as the main character. He resolves issues and grows while struggling hard in response to his boss, who is like a Drill Sergeant and makes unreasonable requests of him.

Our strength (core competence) is "to become a technical partner of our customer engineers." From the past to the present and even in the future ahead, we would like to be an ally of our customer engineers to provide better equipment by working hard and thinking together. We are not allowed to explain everything for confidentiality reasons, but we hope that the universal thoughts and thinking steps of the engineers will provide you with clues for your process improvement and development.

So, before starting SEASON II (practical course), we will introduce a preview of the content. What kinds of difficult requests will our Drill Sergeant make?

Determining the basic specification of the mixing vessel with three information:

operating liquid volume, viscosity and density!

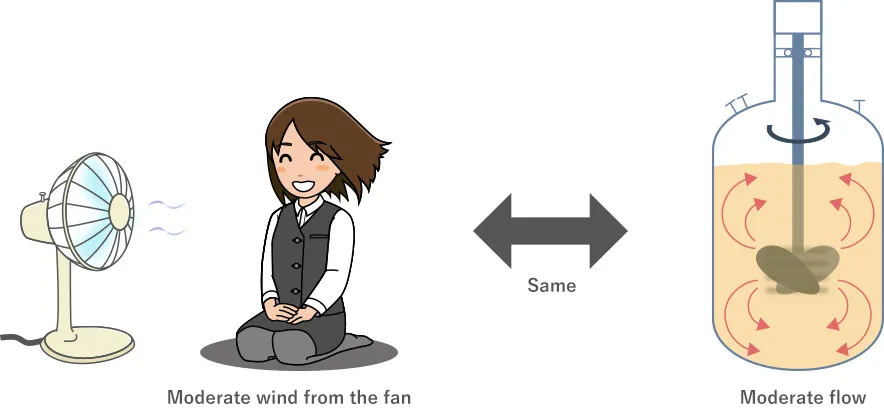

When mixing vessel manufacturers decide on the equipment specifications, they follow a certain thought process. Just as every home appliance maker has roughly decided on the rotational speed settings of electric fans - high, medium and low, there is an approximate level of how much mixing is appropriate for a mixing vessel depending on the use conditions. Here, we will introduce the thought process employed by manufacturer engineers to determine the specifications.

With the laboratory test data from the customer, decide on the actual equipment specifications

and estimate the investment cost right away!!

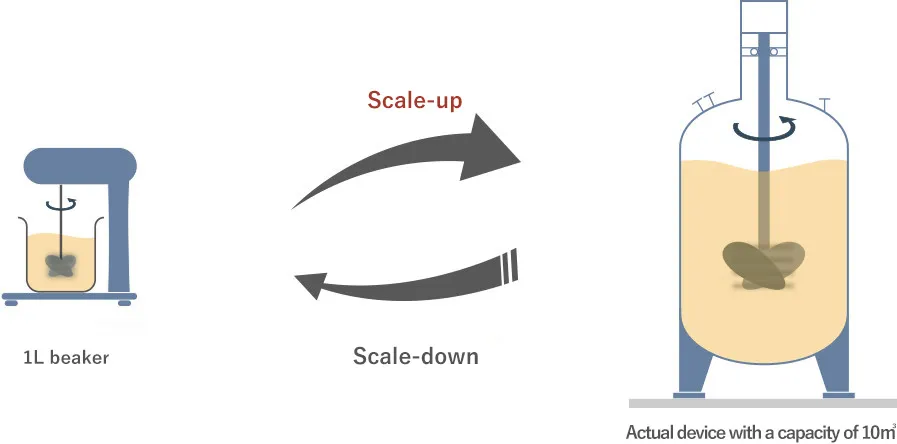

For newly developed products with no in-service usage data, it is necessary to scale-up to the actual machine size based on the beaker scale experimental data. In some cases, the manufacturer may also acquire the chemistry data necessary for scale-up by conducting tests with simulated liquids. This is about scale-up and scale-down.

Provide me with the action plan to improve the productivity of the mixing vessel

in the existing production line!

The improvement of the production efficiency of existing mixing vessels is also a perpetual task for process engineers. It is necessary to analyze each process/operation using the operation chart for a batch and to examine the process that is possibly rate-limiting and its main factors. In order to verify it, it is also necessary to perform scale-down tests on the manufacturer's testing machines.

Give me the action plan to improve the quality of the mixing vessel in the existing production line!

And so on... What do you think? You are facing these problems right now on your site, aren't you?

As we mentioned in the Beginners Course, company engineers have a responsibility to fulfill the QCD (quality, cost & delivery) of the work given. This is not something you can do overnight, but let's enhance "the precise insight" into "the most important thing" little by little by surmounting the orders assigned by our Drill Sergeant.

Stay tuned, keeping in mind the questions as to what is rate limiting in the mixing equipment you are considering.

Also, keep an eye on how our busy engineer will or won't keep the deadline of writing this manuscript!

Now, let's get the Mixing Course SEASON II (practical course) started.

We hope to see you again.

-

Mixing Course

Beginner

course -

- Introduction Basic terms of mixing

- Course 1 Basics of basics: Three points to understand mixing

- Course 2 Examples of the purposes of mixing

- Course 3 Viscosity is the unit of stickiness

- Course 4 Consider a mixing vessel as a huge viscometer

- Course 5 Can you see the flow from power change? (Part 1)

- Course 6 Can you see the flow from power change? (Part 2)

- Course 7 Learn the essence of the mixing Reynolds number

- Course 8 Basics of basics of scaling up

- Course 9 Basics of scaling up

- Course 10 What is heat transfer performance in a mixing vessel?

- Course 11 What is film heat transfer coefficient , hi?

- Course 12 Mixing course review

-

Mixing Course

Practical

course -

- Introduction Mixing course SEASON II

- Course 1 Immediately determine the basic specifications of the mixing vessel using three pieces of information: operating liquid volume, viscosity and density.

- Course 2 Find a plan to improve the productivity of the mixing tank on the existing production line! (Part 1)